|

Site Map MUSLIMS SUSPEND LAWS OF PHYSICS |

|

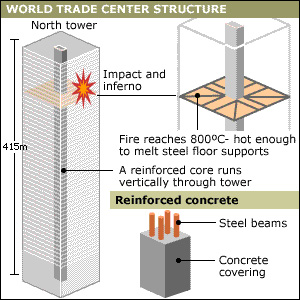

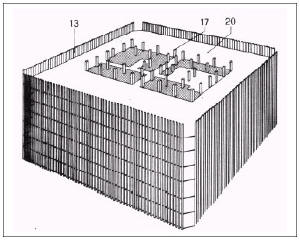

Images cached from BBC page ( http://news.bbc.co.uk/hi/english/world/americas/newsid_1540000/1540044.stm or http://www.public-action.com/911/jmcm/BBCNews ) and HERA report by G. Charles Clifton ( http://www.hera.org.nz/PDF%20Files/World%20Trade%20Centre.pdf or http://www.public-action.com/911/jmcm/clifton.pdf ). Items indicated in Clifton image (right): 13. Exterior columns; 17. Interior columns; 20. Usable office space BBC News Image (left) is misleading: 1. A "beam" is always horizontal, "columns" are vertical. The vertical steel supports in the core were columns. 2. The central columns occupied about 25% of the floor area, not 10% as is shown on the left. 3. The central columns were not encased in a single block of concrete, but interspersed with elevator shafts

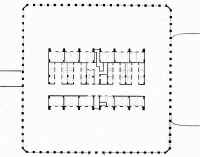

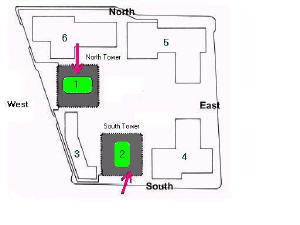

Typical floor plan of WTC tower (from http://www.civil.usyd.edu.au/wtc.htm#system ). The outside shape of the towers was almost square, but the inner core was more rectangular. Pictures from the early phases of construction photos show how the rectangular inner cores were oriented in the finished buildings ( http://www.GreatBuildings.com/cgi-bin/gbi.cgi/World_Trade_Center_Images.html/cid_wtc_mya_WTC_const.4.gbi ). Note that the north tower core was aligned east-west, and the south tower core was aligned north-south. This drawing shows the two WTC towers (black) and the paths of the attacking aircraft (red). Within the profile of each tower, the shape of the central core is shown by the green rectangle. WTC buildings 1 through 6 are numbered, WTC 7, north of 6, is not shown. With the central core bearing the weight of the building, the platters were tied together and stabilized by another set of steel columns at the outside rim, closely spaced and completely surrounding the structure. This resulting structure was so stable that the top of the towers swayed only three feet in a high wind. The architects called it a "tube-within-a-tube design." The TV experts told us that the joints between the floors and central columns melted (or the floor trusses, or the central columns, or the exterior columns, depending on the expert) and this caused the floor to collapse and fall onto the one below. This overloaded the lower floor, and the two of them fell onto the floor below, and so on like dominos (see http://news-info.wustl.edu/News/nrindex00/harmon.html or http://www.public-action.com/911/jmcm/harmon ). Back in the early 1970s when the World Trade Towers were built, the WTC was the tallest building that had ever been built in the history of the world. If we consider the architectural engineers, suppliers, builders, and city inspectors on the job, we can imagine they would be very careful to overbuild every aspect. If one bolt was calculated to serve, you can bet that three or four were used. If there was any doubt about the quality of a girder or steel beam, you can be sure it was rejected. After all, any failures would attract the attention of half the civilized world, and no corporation wants a reputation for that kind of stupidity — particularly if there are casualties. I do not know the exact specifications for the WTC, but I know in many trades (and some I've worked), a structural member must be physically capable of three times the maximum load that will ever be required of it (BreakingStrength = 3 x WorkingStrength). According to Engineering and Technical Handbook by McNeese and Hoag, Prentice Hall, 3rd printing, September 1959: page 47 (Table) Safety Factors of Various Materials, the mandatory safety factor for structural steel is 600%. That is, a steel structure may be rated for a load of only one sixth the actual theoretical limit. Given that none of those floors was holding a grand piano sale or an elephant convention that day, it is unlikely that any of them were loaded to the maximum. Thus, any of the floors should have been capable of supporting more than its own weight plus the two floors above it. I suspect the WTC was engineered for safer margins than the average railroad bridge, and the actual load on each floor was less than 1/6 the BreakingStrength. The platters were constructed of webs of steel trusses. Radial trusses ran from the perimeter of the floor to the central columns, and concentric rings of trusses connected the radial trusses, forming a pattern like a spider web (see http://news.bbc.co.uk/olmedia/1540000/images/_1540044_world_trade_structure300.gif or http://public-action.com/911/jmcm/BBCNews/DOCS/1540044w.gif ). Where the radial trusses connected with the central columns, I imagine the joints looked like the big bolted flanges where girders meet on a bridge — inches thick bolts tying the beams into the columns. In order to weaken those joints, a fire would have to heat the bolts or the flanges to the point where the bolts fell apart or tore through the steel. But here is another thing that gives me problems — all the joints between the platter and the central columns would have to be heated at the same rate in order to collapse at the same time — and at the same rate as the joints with the outer columns on all sides — else one side of the platter would fall, damaging the floor below and making obvious distortions in the skin of the building, or throwing the top of the tower off balance and to one side. |